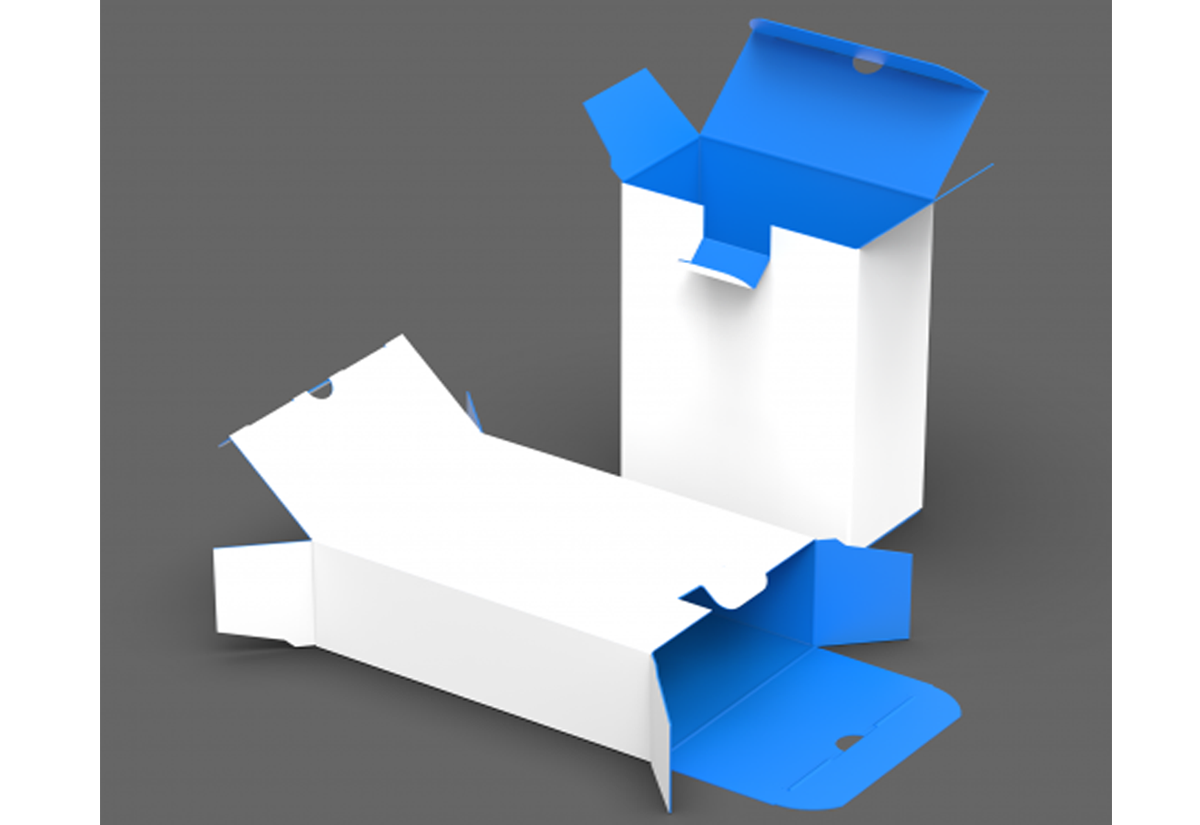

Cardboard Tuck End Boxes of Various Types That Can Be Recycled

Cardboard is the most adaptable material for making your tuck end boxes. It is critical to their commercial success that they are able to recycle.

Cardboard is the most adaptable material for making your tuck end boxes. It is critical to their commercial success that they are able to recycle.

Table of Contents

What are the many types of custom tuck end boxes that can be recycled?

Custom Tuck End Boxes made of cardboard have shown out to be far more useful than we had anticipated. It has propelled the packaging industry to new heights. These boxes are available in a wide range of forms, sizes, designs, and patterns from Custom Boxes.

They have the ability to completely transform the appearance of your products.

These boxes are the most successful at grabbing the attention of customers.

The most efficient method of advertising your business’s identity.

Make each tuck end box according to your preferences to ensure that it has a distinct appearance. This distinguishes your company’s brand on retail shelves.

Various goods may be found in practically every home. As a result, they are the most widely distributed product on the market. Despite the fact that they are packed in reverse tuck end boxes. The bulk of the brands have a rudimentary awareness of the types, designs, and applications of their products.

While expanding your business, you can save money.

The fact that cardboard is recyclable is the most advantageous aspect of its use. You might be able to save even more money by purchasing Kraft straight tuck end boxes. For all of these reasons, we frequently see it as one of the most popular packing options around the world.

What Exactly Is Cardboard?

Prefabricated boxes constructed of cardboard are known as cardboard containers. Companies are currently mass-producing them in an industrial setting on a large scale. They are mostly used for packaging and transportation of commodities and products from one location to another. They’re re-usable, recyclable, and friendly to the environment.

Phase of cardboard production

They’re produced up of natural materials like recyclable pulp. In this method, we turn the wood from the trees into pulp. The pulp is then further processed into a thin sheet of paper.

The thickness of the tuck end boxes can be varied depending on the type of material you use. Furthermore, you can construct anything from small Kraft boxes to large corrugated boxes, depending on your demands.

What Are the Differences Between Different Cardboard Types?

The most common box found in almost every home is the reverse tuck end box. They’re usually divided into the following categories based on their intended function, strength, and long-term durability.

Corrugated Cardboard is a type of corrugated cardboard that is used to make

To make tuck end boxes out of corrugated cardboard. After gluing a fluted sheet between two straight liner boards, fold the two parts together. To strengthen the material’s compressive strength, the horizontal edges are perforated, while the vertical edges are chemically treated.

Configuration of Multiple Walls

Because of its design, it’s great for packaging and transporting a wide range of products. This material can be processed further to make a single, double, or triple walled packing box.

The third option, on the other hand, is the most long-lasting. We make them out of three sheets glued together and sandwiched between four sheets of liner board.

It is used by all of the major manufacturing companies to create the most durable and cost-effective cardboard tuck end boxes. You can also use them to convey products. Because of its light weight, this material is ideal for making display cases.

2. Stiff Kraft

Rigid Kraft is used to make hardbound textbook covers, shoe boxes, cellphone packaging, games, and other goods. The bulk of the time, we make it by gluing Kraft paper layers together with a binder in between. Until we achieve the desired thickness.

The bundle is then pressed again until it achieves the appropriate thickness. Because it is a strong board. It can be printed to give it a unique look. You can also use it to build straight tuck end boxes. This is a term that we frequently use to describe the way we package items. This material is used to construct boxes, particularly for shipping.

3. A cardboard box

To describe this product, we utilize terms like foldable board, cardboard, and boxboard. It has a very thin, smooth outer layer on the outside.

You can use it to manufacture one-of-a-kind cosmetics, cereal, and perfume, food, and beverage containers, among other things. Its ultra-durable security makes it ideal for use in virtually any business.

Despite the fact that it is bendable and has a water-resistant outer layer. It does its best to save the product inside when it is subjected to weight or pressure.

The ability to recycle

There is a prevalent misconception about which types of cardboard can be recycled. In actuality, cardboard recycling is a straightforward process that everyone can perform. It’s available in a number of forms and sizes, and it’s all easily recyclable.

This high-quality material, combined with its capacity to be reprocessed, makes it perfect for use in the packaging industry.

Because the majority of the fiber has already been processed. With this technology, processing pollution has been reduced by nearly 95%.

Which Containers Can’t Be Recycled?

As long as your package is dry and free of contaminants. It’s simple to toss it in the recycle bin. Wet or oily tuck end boxes, on the other hand, are not recyclable. Pizza boxes, fast food containers, and other goods fall under this category.

Materials are waxed.

Waxing boxes clog sorting equipment, leading even the highest-quality materials to be harmed. Other types of boxes with a wax covering or a similar material, such as small juice packing boxes or milk cartons, can also be used. They have a negative impact on their ability to recycle.

Precautionary measures

As a result, always check for the recycling symbol before discarding them in the recycling bin. Any oily cardboard, plastic liners, or bags should be removed from the boxes. Recycling is a straightforward procedure. If you understand the basics of recycling, recycling programmers have a bright future for future generations.

Final Thoughts:

Kraft, cardboard, and corrugated are the most versatile forms of packing material available for building your Tuck end Boxes. The fact that these custom printed boxes may be recycled is the key to their success. custom boxes allow manufacturers to save money while maintaining the greatest level of performance.

We hope it may be of assistance 🙂